Irrigation

A comprehensive line of water control products provides system solutions for the full range of agricultural irrigation such as drip irrigation, pivot systems, sprinklers, micro-jets and greenhouse irrigation, as well as commercial and residential gardening irrigation needs.

Control

LCC Engineering provide solutions for Pumps, valves and meters which offer the confidence of total control for system. Our products are purposely designed to accurately and effectively handle various levels of field pressures and flow rates, in a wide range of applications.

Protect

Ensure protection against water hammer and vacuum situations with our air release valves/ air vacuum valves along with surge disk and thus safeguarding pipelines and system. High inflow and outflow rates, tested operation to surge pressures seals at near zero pressure and auto roll seal mechanisms for dirty water.

Measure

Our products offer precision data recording in large-scale commercial applications for accurate usage analysis and billing purposes. We constantly strive to deliver new and innovative products that meet the ever- changing demands of flow measurement.

Automate

We have wide range of automation control system that runs with up to date technologies in the market synchronised with project application based solutions. We have best in irrigation market control system that synchronises with other SCADA, PLC's and has cloud based operation.

Integrate

We believe in providing integrated turnkey solutions to our partners to achieve application based engineered solutions, maintain high quality performance, carry out efficient operation and obtain economy with low maintenance & high product life.

Drip Irrigation

Drip irrigation can precisely deliver water and nutrients to the crop right at the root zone. Drip Irrigation system is sometimes called trickle irrigation and involves dripping water onto the soil at very low rates (2-20 litres per hour) from a system of small diameter plastic pipes filled with outlets called emitters or drippers. Water is applied close to the plants so that only part of the soil in which the roots grow is wetted, unlike surface and sprinkler irrigation, which involves wetting the whole soil profile. With drip irrigation water, applications are more frequent than with other methods and this provides a very favourable high moisture level in the soil in which plants can flourish. Another advantages for drip irrigation include low application rates, precise water placement and low operating pressures. Drip irrigation can also be used in irregularly shaped fields to maximize the irrigated acreage. Drip irrigation saves water and it's ideal for areas in which water restrictions are imposed.

Sprinkler Irrigation

Sprinkler irrigation is a method of applying water which is similar to natural rainfall but spread uniformly over the land surface just when needed and at a rate less than the infiltration rate of the soil so as to avoid surface runoff from irrigation. This is achieved by distributing water through a system of pipes usually by pumping which is then sprayed into the air through sprinklers so that it breaks up into small water drops which fall to the ground. The system of irrigation is suitable for undulating lands, with poor water availability, sandy or shallow soils, or where uniform application of water is desired. No land leveling is required as with the surface irrigation methods. The water that is pumped through the pump pipe sprinkler system must be free of suspended sediments. As otherwise there would be chances of blockage of the sprinkler nozzles.

Sprinkler irrigation has high efficiency. It however, varies according to climatic conditions, 60% in warm climate, 70% in moderate climate and 80% in humid or cool climate.

Farmer's training

We also provide basic training to farmers for adapting to latest technologies in farming and irrigation by providing knowledge about various techniques and methods along with best farming practices which includes:

- Encouraging micro irrigation methods such as drips and sprinkler system.

- Crop rotation.

- Empowering them to use latest technologies such as irrigation based apps.

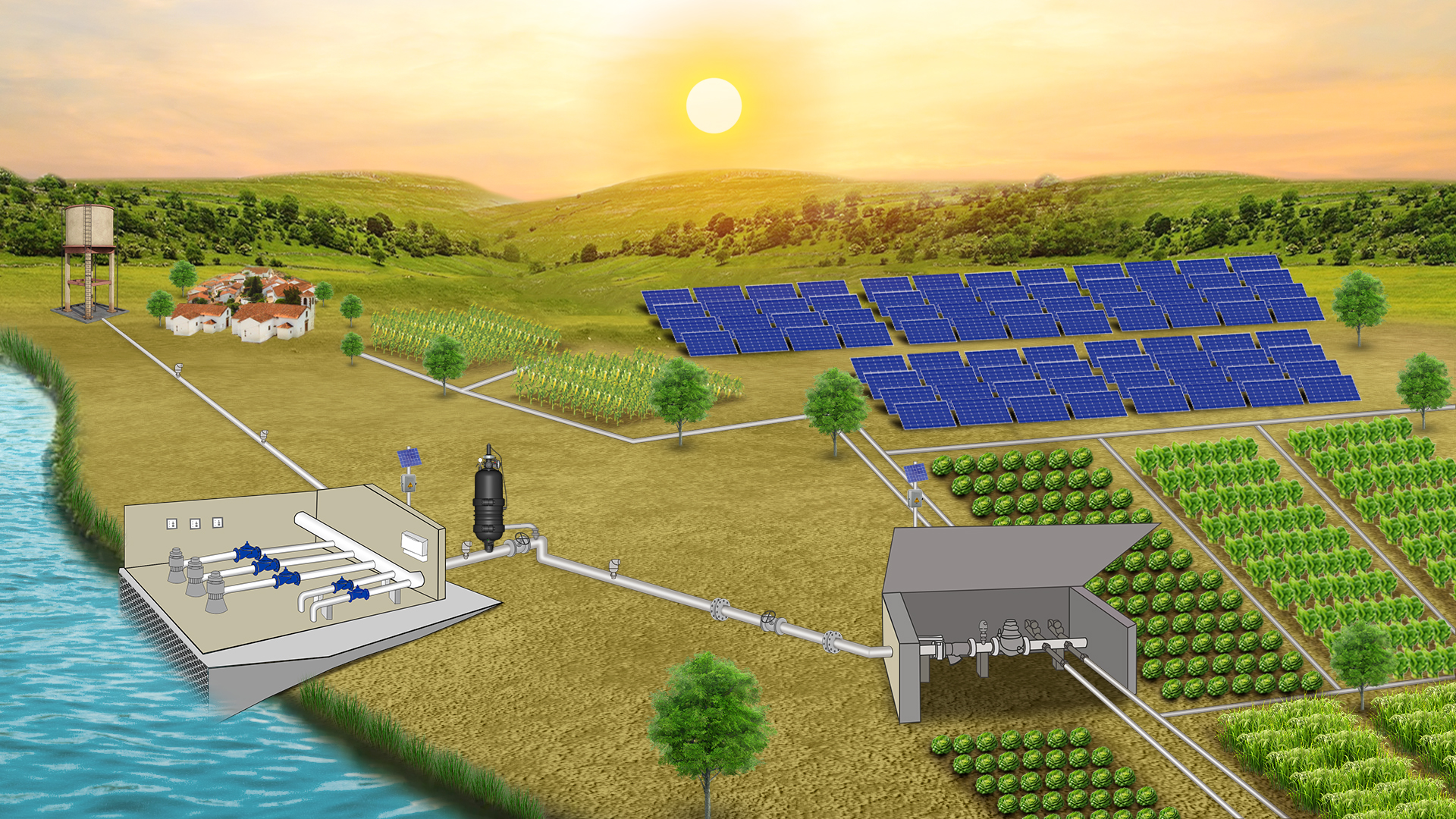

Lift Irrigation System

Lift irrigation schemes accomplish tasks such as to carry water by means of pumps from the water source to the main delivery chamber, which is situated at the top most point in the command area Water is further distributed to the field of the beneficiary farmer's through local distribution network.

Pumping Station and Main Network

This is the part of the project that pertains to the water source and includes major system components such as Booster and large Pump stations, Reservoirs, Main supply lines, pressure and Flow control devices, Automation, Main Control System, Substations etc.

Irrigation system Main Network design and operation starts with careful examination of the available water sources and the physical conditions of the project regarding expected Flow, Pressure, and Quality ranges. Based on these parameters, the project engineer determines the type, size and location of major system components including Pump stations, Reservoirs, Supply lines, Pressure Control Devices, Air Release, Filtration and so on.

These components are then integrated into the Pumping System to achieve Continuous, Reliable, Efficient, and Cost- effective irrigation.

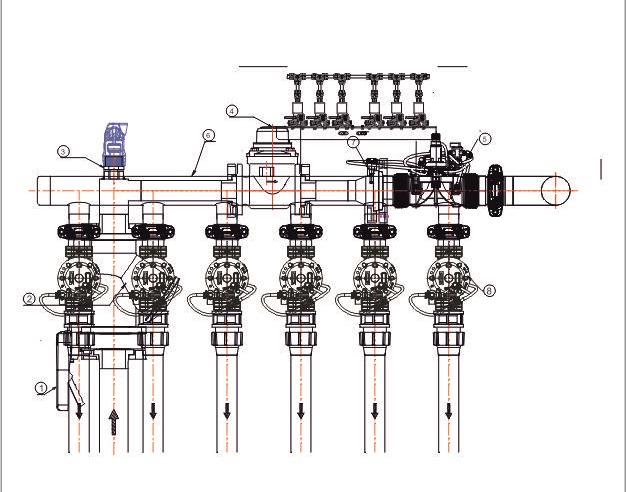

Irrigation Control Head

Here the water supply system is transformed to an Irrigation System. These Irrigation Centers include various types of large size control valves in a variety of applications.

The Irrigation Control Head transforms the Main Network into an irrigation system, with the help of computer control mechanisms.it includes a vantey of applications such as.

- Water metering abilities with outputs to the irrigation controller

- Maintaining of demand and pressure as per system design

- Pressure zoning in accordance with crop, equipment, location and elevation

- Differentiation of irrigation regimes to meet the needs of each crop type and stage

- Central fertilization and filtration systems

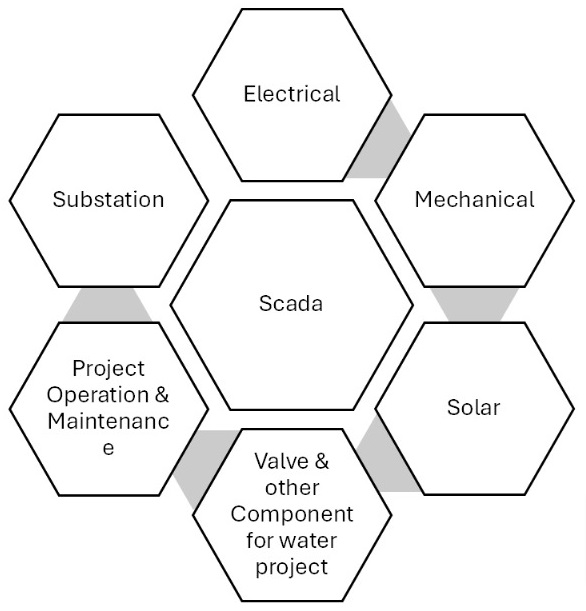

System integrator and turnkey project

Irrigation Projects

- System integration of pumping station Electrical, Mechanical and Automation system.

- System integration of Scada based water distribution to farmers technically called as "Outlet Management system".

Water Supply Projects

- System integration of pumping station electrical, mechanical and automation system.

- System integration of water treatment plant electrical, mechanical and automation system.

- System integration of automation system for water tank.

LCC Engineering, a global company provides support with our wide range of products and solutions implementing it in our offerings as follows:

- Pre Bidding Support with Costing estimation

- Detailed Engineering of Electro Mechanical, Automation.

- Electro Mechanical Designing of Pump Station

- Hydraulic Design and Analysis of Distribution Network

- Designing as well as SITC of AMS, OMS, RMS.

- Designing, Analysis and SITC of precautionary solution for Surge (Water Hammer).

- SITC of Solar Power Plant.

- Operation & Maintenance contract for all above mentioned work.

- Turnkey Projects.

Market Gap & Solution

Client comfortable Area

- Civil Structure

- Pipe Line Lying

Client uncomfortable Area

- Substation

- Pump House electrical,

- Pump House mechanical

- Pump House automation

- Water treatment plant automation in water supply project

- Field automation in irrigation project

- Water tank automation for water supply project

OMS: Outlet Management System

Why Pressurized Systems or Outlet Management System?

- Improves Water use Efficiency: 60-70% Vs. 95%

- Ensures Equitable Distribution of Water

- Reduces land problems & saves on unused area [canals, bridges...]

- Even Farmers in high lands get water

- Saves on unused area

- Speedy Completion of the Project

- Water Meters and Pressure Control

- Computerized Irrigation & SCADA

- Ready for Drip or Sprinklers

(A) PFCMD (PRESSURE FLOW CONTROLLING AND METERING DEVICE)

The hydraulically operated self-actuated control vale at chak level (e.g. 20 Ha) is capable of controlling Pressure and measuring the flow by same valve known as PFCMD (Pressure flow controlling and metering device). The valve shall have integrated into one body, vertical turbine Woltman-Type water meter with a diaphragm actuated hydraulic control valve. The valve is compatible with cloud based control system and SCADA system.

The valve has integrated inlet and outlet flow straighteners to eliminate the need for straight pipe installation requirements.

(B) ON/OFF OUTLET FIELD CONTROL VALVES (FCV)

Outlet field control valves (FCV) shall be hydraulically operated, diaphragm actuated control valve. The control valve are open and close drip-tight in response to an electric signal, which causes the solenoid to open or close the valve's internal hydraulic loop. The valve shall be oblique (Y pattern) with "Look Through" design to have high flow capacity Low pressure loss. The body and cover shall be Glass-Filled Nylon material.

(C) COMBINATION AIR VALVE

Every chak outlet valve is installed with combination air valve. It evacuates air during pipeline filling, allows efficient release of air pockets from pressurized pipes and enables large volume air intake in the event of network draining

(D) STRAINER

Every chak outlet valve is installed with Y Type Strainer, which is designed to remove foreign matter such as stones, sticks etc. from the pipeline. It is installed upstream of control valves. The Y Type strainer of 200 microns screen is provided.

(E) ISOLATION VALVE

Every chak outlet valve is installed with Isolation valve to have control sub-chak valve during maintenance. Isolation valve is operated manually

(F) SOLENOID VALVE

Every chak outlet valve is installed with Solenoid valve, which operates (on/off) command received from the RTU/Controller in the control center. Function of this Solenoid valve is to hydraulically on/off the sub-chak valves. The solenoid is 12V DC latching solenoid. The solenoid valve is housed in theft proof metallic protection box.

(G) RADIO FREQUENCY BASED-REMOTE TERMINAL UNIT (RF-RTU)

Every chak outlet valve is installed with RF-RTU. Function of this RTU is to receive the Radio Frequency commands from the controller stationed in the control center and to operate the solenoid on/off function as per the schedule or need of the system operation. The RTU uses inbuild rechargeable battery of 10AH. The RTU box is made of IP-67. This RF-RTU operates on License free band of 865.2-866.8 MHz.

This RF-RTU transfer the data to SCADA about battery charging status, battery voltage & generate alert on low battery. Also, the radio signal quality is monitored in the SCADA and update on poor signal strength.

(H) SOLAR PANEL

Every chak outlet is installed with Solar panel, which is mounted on 6m height pole to be out of reach from people for day to day purpose. The function of Solar panel is to recharge the rechargeable battery in the RTU.

(I) PROTECTION BOX

In every chak outlet, valve skid of all the components is be protected with tamper proof protection box with lock and key arrangement, the protection box provided is generally metallic box or specified as per contractor. However, to protect them from theft, protection box made of metallic box or concrete is provided with tampering sensor. It will generate alarm when unauthorized person is trying to open or temper the box

(J) IC (IRRIGATION CONTROLLER)

Irrigation controller is installed in central control room at pump station and in the field in strategic location as needed. This irrigation controller will be programmed for valve on/off as per the need. This controller uses license free band radio frequency to communicate with RF-RTU at every chak outlet and synchronizes with cloud by data through SIM card in controller or GPRS connection. This controller has got capability to auto schedule the valve planning of the day based on Evapro-Transpiration basis. The mobile/remote communication/operation is possible through cloud.

(K) PC & SCREEN AT CONTROL CENTER

PG/computer with display screen is installed in at central control room of the scheme. The cloud installed on PC/computer communicates with the IC's in the field and gather the data to display the live running status of the scheme. It gives alerts, reports and user-friendly interface, which allows easy monitoring and modification in the running scheme.