Water Supply Projects

Engineering, Products & Accessories

LCC Engineering offers and integrates various electro mechanical components like Pumps, Motor, Cranes, Expansion joints, Surge protection devices SCADA and Automation etc. along with their selection and designing.

Reservoirs and Water Storage management system. (RMS)

Reservoirs are an important component in every water supply system because of their use for various applications such as:

- Storage

- Energy and Cost Saving (reducing pumping hours)

- Pressure Reducing at down-hill lines

Replacing the manual valve, the Altitude Valve turns water level control into an automatic function. The valve is equipped with an altitude pilot, which constantly reads the water level of the Elevated Reservoir. The pilot maintains a constant differential between opening and closing, so that the valve shuts off at a pre-set reservoir high level, and fully opens in response to a drop in water level.

Level Control Valves:

Purpose:

- To Prevent overflow from the reservoir

- To Maintain minimum level

Position:

- Reservoir inlet (during filling)

- Reservoir outlet (during emptying)

Function:

- Automatically control the water level

Air Management System

Critical importance of Air Control in pressurized water pipelines & networks

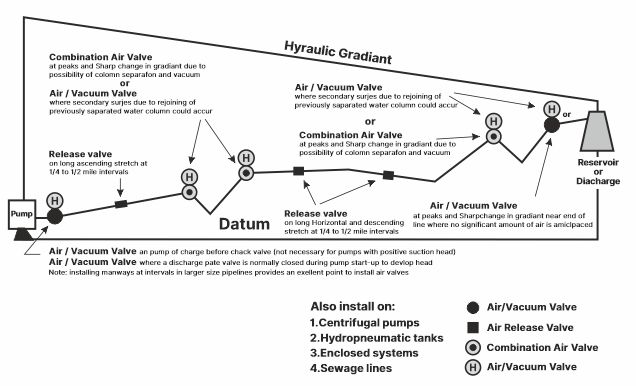

Controlling air is one of the important factor in water supply or lift irrigation schemes. There is always some amount of entrapped air present in the system or pipeline which is conveying water thus reduce flow area, increase energy costs during pipeline filling and pressurized operation, cause pressure surges, interfere with metering or even stop the flow altogether. In addition, there are cases where air cannot enter the network. This can cause vacuum conditions and may lead to pipes collapsing or other mechanical damage to system components.

We provide efficient Air valves which are essential for air control in water systems. They help to prevent inefficiency caused by air that is trapped during filling (Kinetic air valves) and pressurized operation (Automatic or Air release function, as well as to prevent damage in vacuum conditions (Kinetic air valves) and pressure surges (Triple acting or Air Cushion Valve).

Typical pipeline and position of necessary air valves

Surge Phenomena & Protection Methods

What is Water hammer / Surge?

Water Hammer or Pressure Surges are Caused when a fluid in motion is forced to stop or change velocity suddenly. The compressibility of the liquid and the elasticity of the pipeline cause a transient pressure wave to propagate throughout the system. The magnitude of this transient pressure can cause system hydraulic components to fail Such as Pipe burst, Expanssion daints failure.

LCC Engineering surge solutions

- Control valves

- Surge tanks

- Air valves

Surge analysis procedure

- Creating a model

- Case studies

- Data for surge analysis

Surge anticipating valves + air valves solution = Valves deal with positive surge and air valves deal with negative surge

Surge tank + air valves solution Surge tank handles both positive and negative pressure surges, but air valves may reduce the size of the tank